BioNator®-System

The best of Germany beyond national borders

The challenge of procuring inexpensive water for use in industrial processes is not exclusively a German problem. All countries deal with water resources in a more conscientious manner nowadays than they did a number of years ago.

Following the quality seal “Made in Germany”, our neighbours like to draw on the achievements of German engineering. Just like a Swiss army knife, the BioNator® system is flexible and sophisticated. It can adapt to on-site conditions and is an excellent and reliable complement to Swiss systems.

This process water recovery system clarifies up to 2m³ of process wastewater a day, just like clockwork. The BioNator® system, like all systems from aquadetox international, completely does away with the addition of flocculants and disinfectants.

The BioNator’s biological treatment process ensures that legal regulations and requirements of other countries regarding the quality of the recycled water are observed. All accumulated wastewater can therefore safely be fed into the sewage system after the purification process. Depending on the plant on site, the cleaned wastewater can be reintroduced into the process cycle, which makes fresh water savings of up to 98% possible.

Individual on-site requirement analyses and plans ensure that every system at every location is designed and constructed precisely for the use for which it was conceived.

BioPower®-System

Tried and tested lamella clarifiers still exist

The amount of water needed for in-house processes often necessitates large dimensions. This ultimately also determines the costs for procuring the fresh water needed and the usually much greater costs of disposing of the wastewater. Naturally, the level and type of contamination play a major role here.

Many contaminants have a higher density than the water in which they are dissolved. Substances with a particle size of >50 μ can be filtered out of the process water by sedimentation. It is precisely this force of nature on which the BioPower® system is based. The compact lamella clarifier system receives the process water up to 1.5m³/h directly at the process wastewater accumulation point and separates the harmful substances from the usable water, all without adding flocculants or separating agents. The end of the impact cycle results in biologically recycled wastewater which is guaranteed to adhere to the limit values and can be reintroduced into the process cycle. Waste material is also produced which can be disposed of more efficiently in smaller dimensions.

Users of the BioPower® system make fresh water savings of up to 85%. In addition to these advantages, it is easy to retrofit and it requires little maintenance. For many years now, the BioPower® system has proven itself in car dealerships, across the car wash sector and beyond.

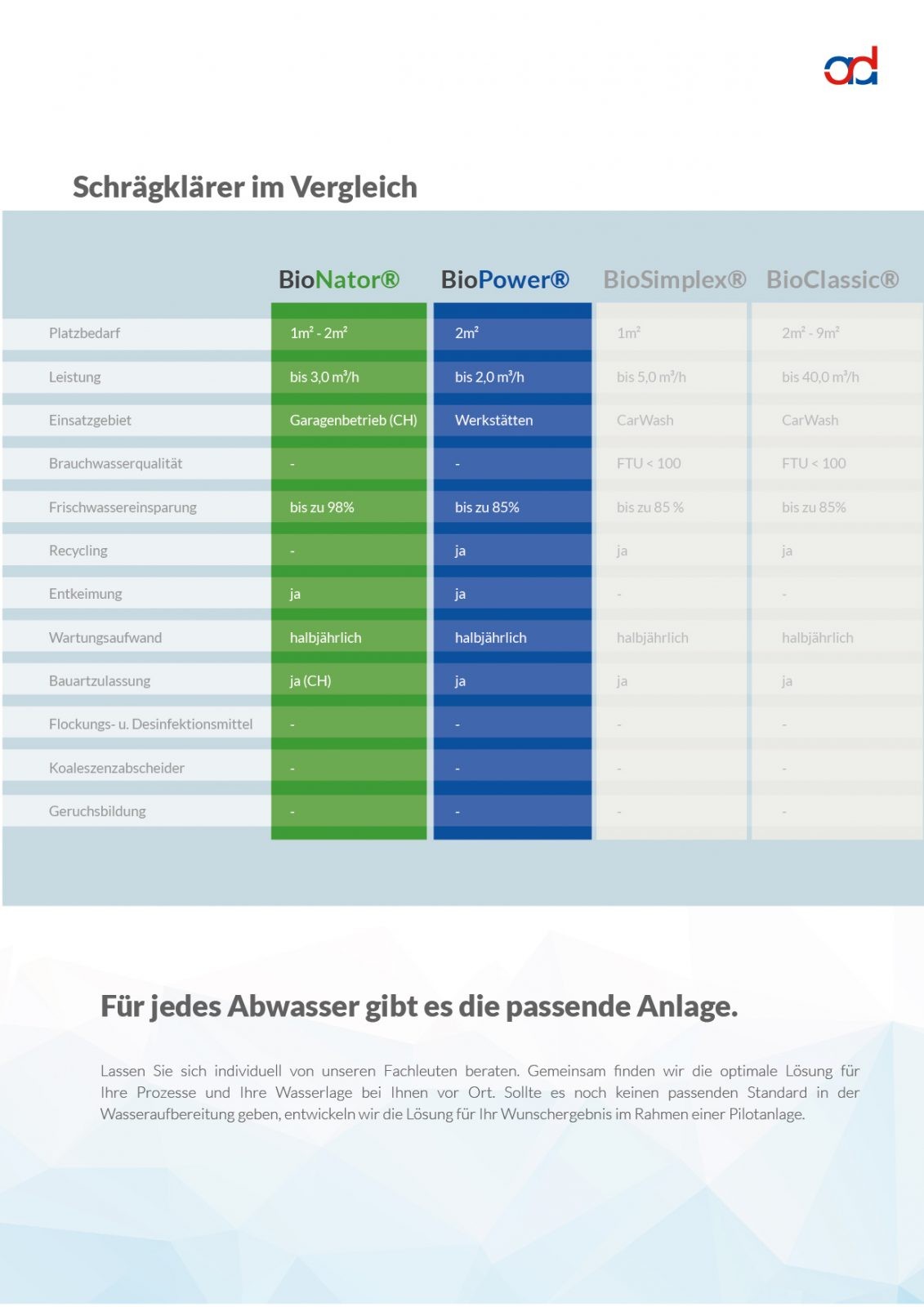

A comparison of lamella clarifiers

Comparative Values

BioNator®

BioPower®

Space required

1m² – 2m²

from 2m²

Performance

up to 3,0 m³/h

up to 2,0 m³/h

Areas of application

Garages (CH)

Workshops

Process water quality

–

–

Fresh water savings

up to 98%

up to 85%

Recycling

–

yes

Sterilisation

yes

yes

Maintenance

twice a year

twice a year

Type approval

yes (CH)

yes

Flocculant and disinfectant

–

–

Coalescence separator

–

–

Odour

–

–

Our products compared

in our PDF-Download

Am Langenberg 2

88317 Altmannshofen

Telefon: +49 (0) 7565/9805-0

Telefax: +49 (0) 7565/9805-19